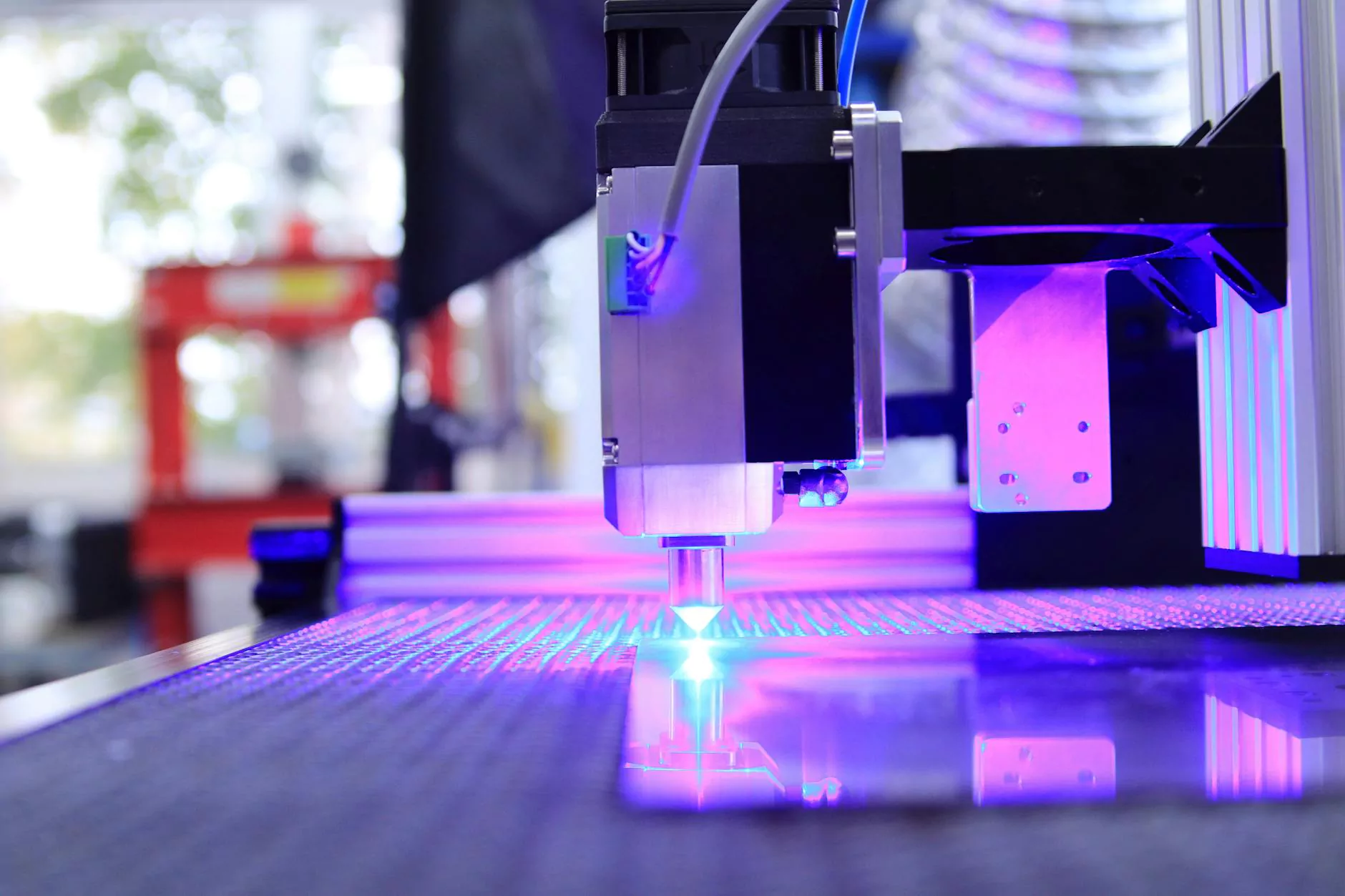

Enhancing Business Opportunities with Roctek CNC Machines

In today's fast-paced industrial landscape, businesses are constantly seeking ways to improve efficiency, reduce costs, and enhance product quality. One of the most effective solutions lies in the integration of advanced technology, particularly through the use of CNC (Computer Numerical Control) machines. Among the prominent players in this field is Roctek, a name synonymous with precision engineering and innovative manufacturing solutions. This article delves into the remarkable world of Roctek CNC machines, exploring how they can transform your business operations and provide a competitive edge.

Understanding CNC Technology

CNC technology revolutionizes the manufacturing process by automating the control of machine tools through a computer program. Unlike traditional manual machining, CNC machines can operate continuously with high precision, making them perfect for both high-volume production and intricate custom projects. With Roctek's advanced CNC systems, businesses gain access to unparalleled accuracy and efficiency, translating to increased productivity and minimized waste.

The Roctek Advantage

When it comes to CNC machines, Roctek stands out for several compelling reasons:

- Precision Engineering: Roctek machines are designed to achieve tight tolerances, ensuring that every part produced meets the highest quality standards.

- Robust Build Quality: Built to withstand rigorous manufacturing demands, Roctek machines feature high-quality materials and engineering that enhance durability.

- Intuitive User Interface: Roctek CNC machines come equipped with user-friendly controls and software, enabling operators to easily program and monitor their production runs.

- Comprehensive Support: With a dedicated customer service team, Roctek provides extensive support, ensuring that businesses can maximize their machine's capabilities.

Applications of Roctek CNC Machines

Roctek CNC machines are versatile tools that can be customized for a wide range of applications across various industries:

1. Aerospace and Defense

Aerospace manufacturing demands high precision and reliability. Roctek CNC machines can produce intricate components such as turbine blades and airframe parts with utmost accuracy, adhering to strict regulatory standards.

2. Automotive Industry

In the automotive sector, Roctek machines excel in manufacturing engine components, transmission parts, and custom tooling. Their ability to operate at high speeds without sacrificing quality makes them a preferred choice for automotive manufacturers.

3. Pharmaceutical Manufacturing

With stringent hygiene and quality requirements, the pharmaceutical industry relies on Roctek machines to produce equipment parts and containers that meet exacting standards, ensuring compliance with health regulations.

Maximizing Efficiency with Roctek

Implementing Roctek CNC machines in your production line can yield significant efficiency improvements:

- Reduced Cycle Times: CNC machines operate faster than manual machines, significantly decreasing production times.

- Consistency and Repeatability: Once programmed, Roctek machines can produce identical parts with extreme precision, eliminating variability.

- Lower Labor Costs: By reducing the need for skilled manual labor, companies can save on labor costs and allocate resources more efficiently.

Case Study: A Success Story with Roctek

To illustrate the impact of Roctek CNC machines, let's examine a hypothetical auto parts manufacturer, XYZ Auto. By transitioning from manual machining processes to Roctek CNC machinery, XYZ Auto experienced:

- 30% Increase in Productivity: With automated processes, XYZ Auto could meet rising demand without hiring additional staff.

- 20% Cost Reduction: The efficiency of Roctek machines allowed XYZ to lower production costs while maintaining quality.

- Improved Lead Times: Order fulfillment times dropped by 15%, enhancing customer satisfaction and retention.

Investing in Roctek: A Smart Financial Decision

While the initial investment in Roctek CNC machines may seem significant, the long-term savings and benefits far outweigh the costs. Here’s why:

- Increased Output: Higher productivity means that businesses can increase their revenue without a proportional increase in costs.

- Lower Maintenance Costs: Roctek machines are designed for longevity, meaning lower maintenance costs over time.

- Scalability: As your business grows, Roctek machines can adapt to varying production needs without the need for complete overhaul.

Conclusion: The Future of Manufacturing with Roctek

In conclusion, Roctek provides an invaluable asset for businesses looking to enhance their production capabilities through advanced CNC technology. By investing in Roctek CNC machines, manufacturers not only improve operational efficiency but also position themselves for future growth in an ever-evolving market.

As you consider your options for CNC machinery, remember that Roctek stands ready to elevate your business to new heights. With its commitment to quality, innovation, and customer support, Roctek is not just a purchase; it’s a partnership for success in the competitive landscape of modern manufacturing.